Quality Solutions

We deploy the most qualified quality engineers and auditors to deliver efficient, reliable, and customized quality assurance solutions.

Our services

Our Quality Control Inspection Services are designed to attend your business interest

Factory Audit

Even if you have already worked successfully with a manufacturer, they must continue to produce high quality products. However, many importers who work with manufacturers from low-wage countries have found that quality declined after a few years, even though the collaboration started out solidly.

Factory audits are a tool that can help you to avoid these problems. We’re able to perform the following Factory Audits depending on Your demand:

Capability audits to help verify whether the factory can manufacture your product within the set timelines.

Quality audits to measure whether the supplier has an effective quality management system in place (Based on ISO9001 standards).

Social compliance audits to assess working conditions and ensure no human rights violations occur, such as child labor.

Environmental audits to verify whether the factory complies with environmental standards and requirements.

Process Audit

Pre-Production Inspection (PPI)

A PPI can be an advantage when working with a new supplier, especially if your project is a large order with critical delivery dates. It is also very important if you suspect that the supplier has tried to cut costs by using lower-cost materials or components prior to production.

First Sample Inspection (FSI)

During Production Inspection (DPI)

These quality control inspections are performed during production when only 10-15% of the units are completed. During this inspection, we identify discrepancies and provide feedback on corrective actions. In addition, we re-inspect the defects identified during the pre-shipment inspection to confirm that they have been corrected.

Pre Shipment Inspection (PSI)

For all inspections, IQAS Services uses the applicable standards and statistical sampling procedure. These comprehensive criteria cover: functionality, performance, durability, overall appearance, and dimension. Inspection certificates are issued if stipulated in the letter of credit.

Container Loading Inspection (CLI)

Sample Testing

Why IQAS Services?

We control in accordance to our customers specifications and requests. Based on our experience we suggest potential solutions for improvement.

Your Eyes In The Factory

IQAS Services works on your side to protect your business interests in the supply chain. We ensure that all products meet your Quality Standards, keeping the costs of quality problems at the factory.

Personalized Service

IQAS Services provides personalized, tailor-made services to its clients, including but not limited to: a dedicated account manager, a personalized report format, and a mutually agreed checklist.

Value For Money

Get competitive pricing that doesn‘t sacrifice service quality or reliability. No hidden costs or additional charges. Get your All-inclusive Quote before confirming the inspection.

Fast Reports Delivery

All Inspection and Audit Reports are sent before 6 PM CET Time on the same day of service. This saves you 24h compared to other inspection companies and allows you to take critical decisions early on.

Global Coverage

Global network of highly-qualified technical inspectors and auditors, operating across the World in different countries and regions.

Ready to improve Quality Performance?

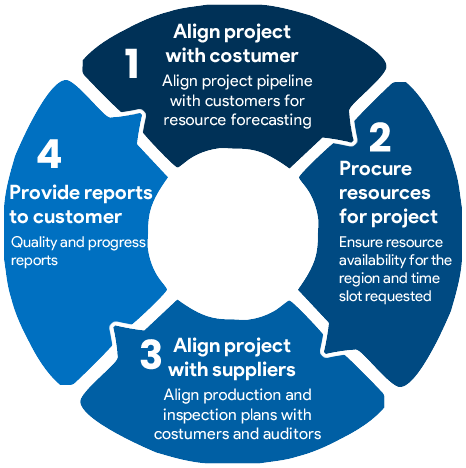

Main steps of the process for an inspection project

Product inspection is a crucial step in supply chain and quality control processes. It includes various stages of the production process and before shipment. You’ll be able to verify the product quality on-site to prevent quality issues and supply chain disruptions.

Improve Product Quality with IQAS

Our Quality inspectors are very well experienced

and trained to fulfill our customer’s demands.